Brushless DC electric motor

BLDC motors, BL motors also known as electronically commutated motors (ECMs, EC motors) are synchronous motors powered by DC electricity via an inverter/switching power supply which produces an AC/bi-directional electric current to drive each phase of the motor via a closed loop controller. The controller times commutation (hence rpm) and creates current waveforms (hence torque). In this context alternating current does not imply but does include a sinusoidal waveform, with minimal restriction on waveform; it must be periodic, and its frequency will determine motor rpm, and the waveform does affect how smooth the generated torque is as well as the motors efficiency at transforming electrical to mechanical energy. In a well designed PMSM the air gap magnetic flux is spatial sinusoidal and the phase commutation currents are sinusoidal, ninety degrees out of phase.

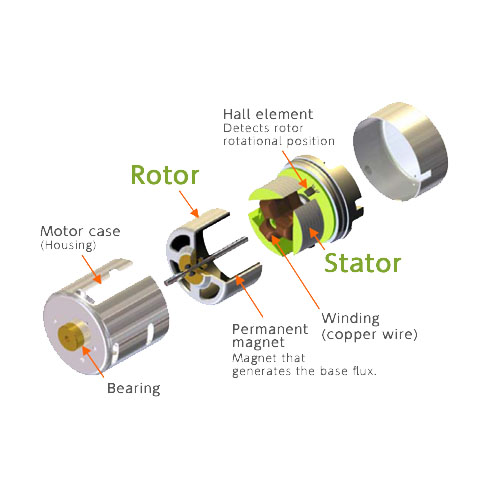

The motor structural elements of a brushless motor system is typically permanent magnet synchronous motor, but can also be a switched reluctance motor, or induction motor.

Brushless motors may be implemented as stepper motors as well; however, the term “stepper motor” tends to be used for motors with a radically different design and controlled with an open loop (hence the controller cannot detect when the stepper does not step due to too high shaft load; there is no shaft position sensor). They are frequently stopped with the rotor in a defined angular position while still producing torque. A well design power supply/controller/PMSM can also be held at zero rpm and finite torque. Two key performance parameters of brushless DC motors are the motor constants Kt ( torque constant) and Ke ( BEMF constant also known as speed constant Kv = 1/Ke ).

Brushless vs brushed motors (Brushless DC electric motor)

Brushed DC motors have been around since the mid-19th century, but brushless motors are a fairly recent arrival; a first step in the 1960s thanks to advances in solid state technology,[3] with further improvements in the 1980s thanks to better permanent magnet materials.

Brushed DC motors develop a maximum torque when stationary, linearly decreasing as velocity increases.[4] Some limitations of brushed motors can be overcome by brushless motors; they include higher efficiency and a lower susceptibility to mechanical wear. These benefits come at the cost of potentially less rugged, more complex, and more expensive control electronics.

A typical brushless motor has permanent magnets which rotate around a fixed armature, eliminating problems associated with connecting current to the moving armature. An electronic controller replaces the brush/commutator assembly of the brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs similar timed power distribution by using a solid-state circuit rather than the brush/commutator system.

Brushless motors offer several advantages over brushed DC motors, including high torque to weight ratio, more torque per watt (increased efficiency), increased reliability, reduced noise, longer lifetime (no brush and commutator erosion), elimination of ionizing sparks from the commutator, and overall reduction of electromagnetic interference (EMI). With no windings on the rotor, they are not subjected to centrifugal forces, and because the windings are supported by the housing, they can be cooled by conduction, requiring no airflow inside the motor for cooling. This in turn means that the motor’s internals can be entirely enclosed and protected from dirt or other foreign matter.

Brushless motor commutation can be implemented in software using a microcontroller or microprocessor computer, or may alternatively be implemented in analogue hardware, or in digital firmware using an FPGA. Commutation with electronics instead of brushes allows for greater flexibility and capabilities not available with brushed DC motors, including speed limiting, “micro stepped” operation for slow and/or fine motion control, and a holding torque when stationary. Controller software can be customized to the specific motor being used in the application, resulting in greater commutation efficiency.

The maximum power that can be applied to a brushless motor is limited almost exclusively by heat;[citation needed] too much heat weakens the magnets[5] and may damage the winding’s insulation.

When converting electricity into mechanical power, brushless motors are more efficient than brushed motors. This improvement is largely due to the frequency at which the electricity is switched determined by the position sensor feedback. Additional gains are due to the absence of brushes, which reduces mechanical energy loss due to friction. The enhanced efficiency is greatest in the no-load and low-load region of the motor’s performance curve.[citation needed] Under high mechanical loads, brushless motors and high-quality brushed motors are comparable in efficiency.